Automobiles have a tremendous effect on the environment. From their initial production through final disposal in junkyards, traditional manufacturing methods cause pollution, resource depletion and greenhouse gas emissions.

Car manufacturers can lessen their environmental impact by adopting circular economy principles, recycling materials and components and cutting energy consumption during production.

Reusing Existing Materials

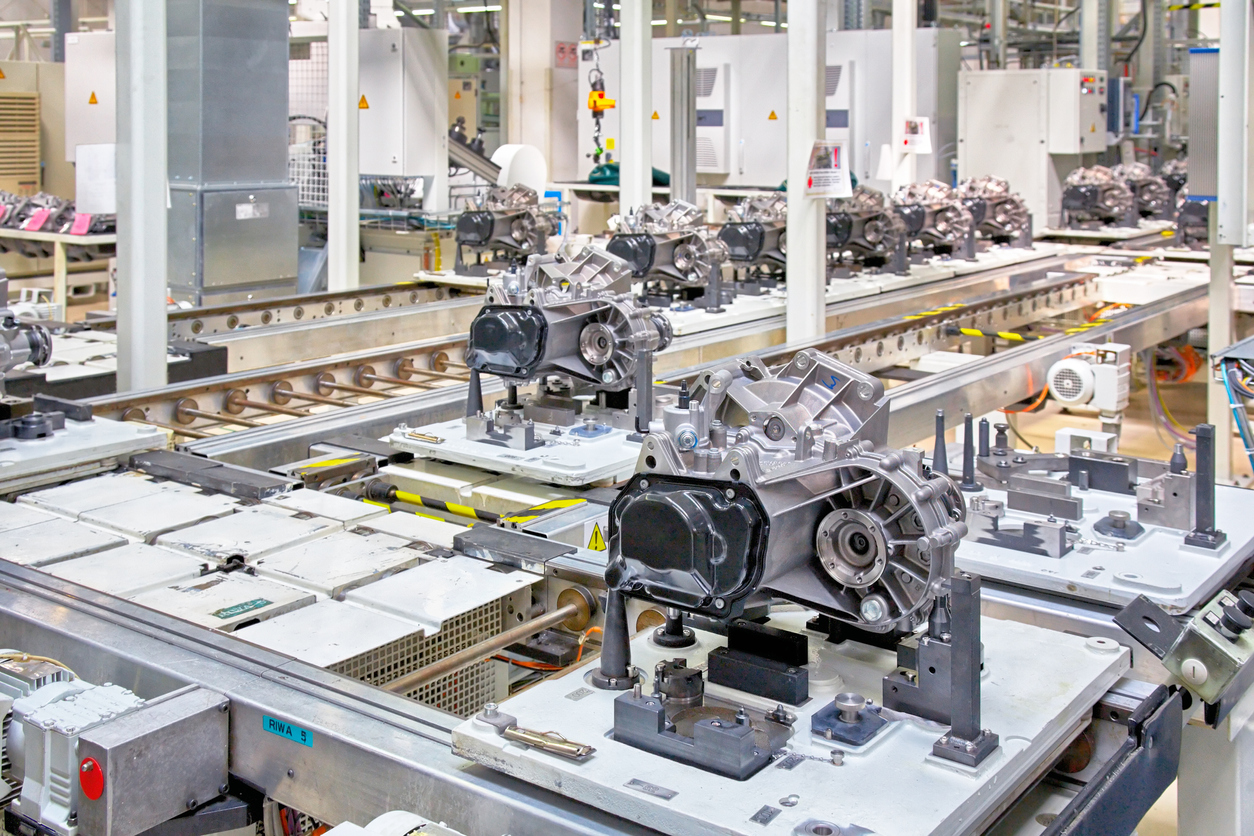

Cars contain thousands of components made from iron, steel and aluminium that together account for much of their material demand and greenhouse gas emissions. This makes them one of the largest contributors to material utilization.

These materials can be recycled at the end of their working lives; however, a lack of coordination between manufacturers and dismantlers is impeding this process.

Modern auto recycling requires an in-depth process that maximizes the amount of materials salvaged for reuse and recycling, and requires significantly less energy than manufacturing new materials, significantly lowering environmental impacts.

However, reaching zero waste can be more challenging. Even the most eco-conscious companies produce offcuts and remnants which must be disposed of, while transport of raw materials and finished parts adds significantly to an industry’s carbon footprint. To reduce these impacts, more eco-friendly manufacturing techniques should be adopted like additive manufacturing that reduces material usage as well as emissions from machines.

Reducing Waste

Car manufacturers are striving to reduce waste during production by employing renewable energy and recycling materials in production methods.

Auto companies are actively taking steps to reduce waste during the transportation of their parts. By employing recyclable packaging and decreasing their use of shipping containers, as well as replacing wooden pallets with metal ones – helping eliminate extra padding that creates additional waste – auto companies are taking strides toward becoming greener companies.

At the end of their useful lives, auto parts are taken to recycling facilities where they undergo an array of steps involving sorting. Metal pieces are melted down and used in new metal products while plastics and rubber materials are ground into pellets that can then be recycled back into new plastic and rubber materials, saving resources while decreasing mining needs. This process helps save both natural resources as well as mining costs.

Recovering Precious Metals

Auto parts are manufactured using various materials, including precious metals. Although in high demand and often subject to supply chain disruptions, sustainable strategies such as microbial biotechnology may offer an economical and ecological way of meeting rising demand for these materials.

Modern cars are made almost entirely out of recycled steel, which significantly decreases energy use, pollution levels, and mining needs. Copper, aluminum and lead used for battery wiring can also be reused or recycled – while oil, gas and operating fluids can be safely drained off, stored away until disposal time.

Other eco-friendly manufacturing processes include reducing water use, using renewable energy sources and optimizing waste management systems. Adopting these practices can greatly lessen the impact that automotive industries have on the environment – both carbon emissions and resource consumption – with recycling also saving car owners money as they pay less for replacement or new parts.

Embracing Sustainable Manufacturing

Sustainable manufacturing practices bring many advantages, including reduced energy use and waste generation. Furthermore, adopting these eco-friendly practices promotes innovation in product design and materials sourcing – benefits which extend far beyond just reduced carbon emissions.

Implementing sustainable manufacturing techniques requires dedication from every member of the supply chain. This includes including green materials in components, using secondary raw materials, reducing energy consumption and tapping renewable sources, while eliminating industrial waste. Manufacturers should invest in efficient equipment while limiting water usage for maximum environmental impact minimization.

Sustainable materials help companies meet consumer demands while simultaneously strengthening their brand image to appeal to eco-conscious buyers. Not only can such practices benefit the environment; they may be less costly and more profitable than their conventional alternatives, making meeting regulatory standards and customer expectations easier as well. To learn more about how sustainability can benefit your business, download this complimentary fact sheet by SAP and Oxford Economics: Keeping the Bottom Line While Balancing the Green Lines.